Sig J-3 1/4 Scale Cub Build Series – Part 3 – Stabilizer & Elevator

Category : Model Airplane Building

Part 3 – Horizontal Stabilizer and Elevator

Building the horizontal stabilizer and elevator are pieces that can also be constructed quickly.

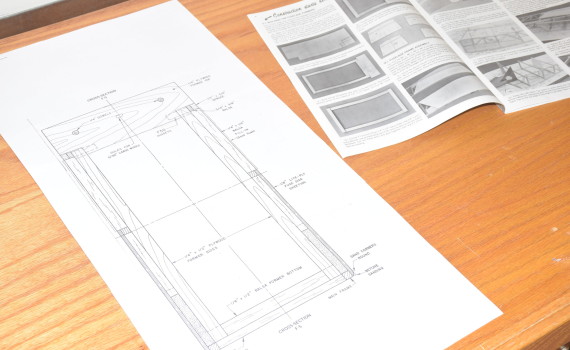

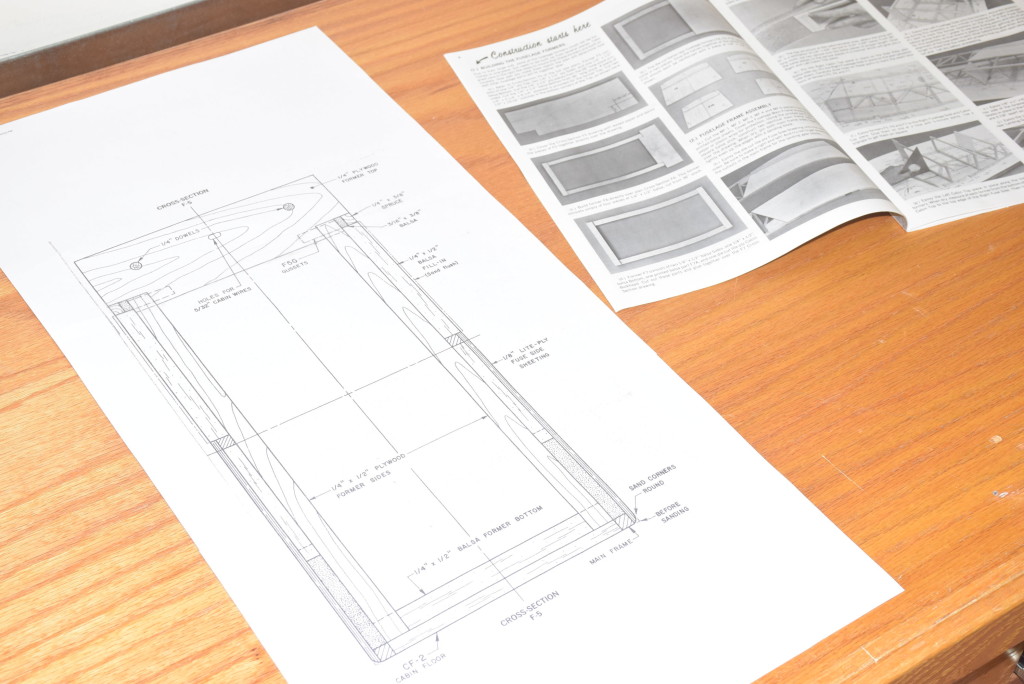

Most pieces for the horizontal stabilizer and elevator are included on printed 3/8 balsa sheets. Be sure to also set aside the included stick pieces you will need for this build and make sure they are of the proper thickness as shown on the plans.

I started by rough cutting the printed pieces on a band saw. Since there are quite a number of pieces it best to do this while your mind is fresh. Having to cut out all these pieces can be a little time consuming and start to feel repetitive.

Elevator

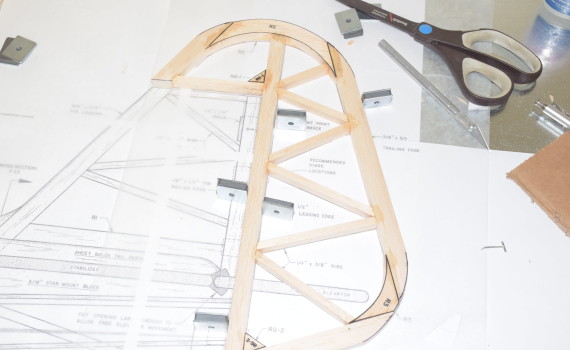

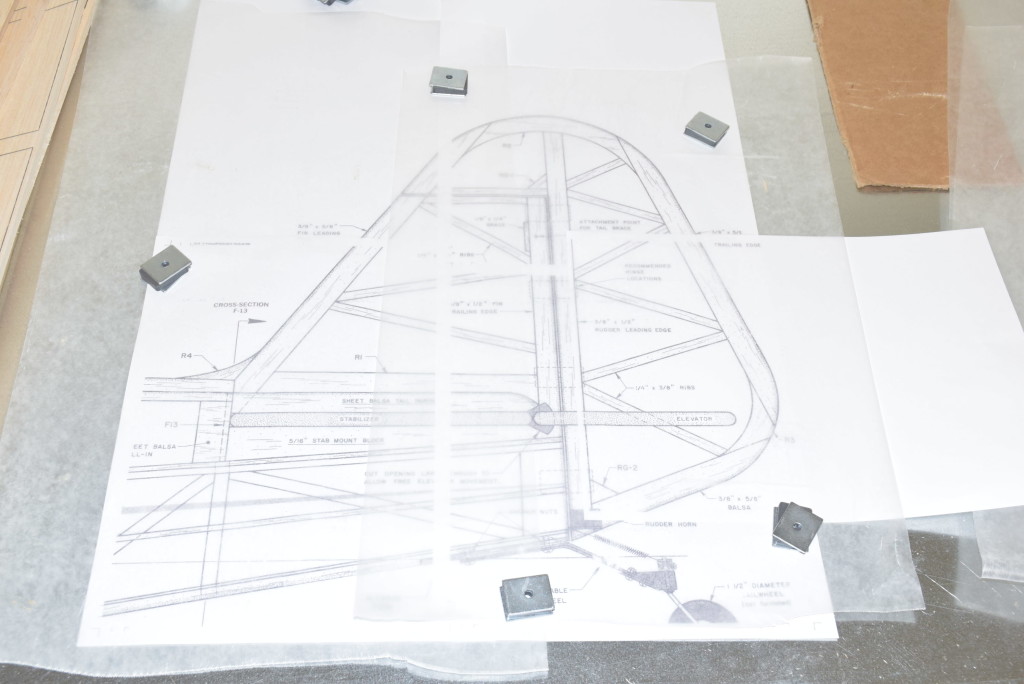

Once all the parts were cut out, I set them aside and started with placing the 3/8 x 1/2 inch balsa sticks in place over the plans. There is also a 3/8 spruce center piece. I placed the spruce piece over the plans as accurately as possible and then cut the two 3/8 balsa outside sticks just a hair longer than needed. Use a straight edge to make sure the sticks are as straight as possible along the hinge line. This will help reduce any hinge gaps later during assembly. I placed the E6 and E1 parts in place over the plans along with the spruce elevator horn block and glued this sub-assembly.

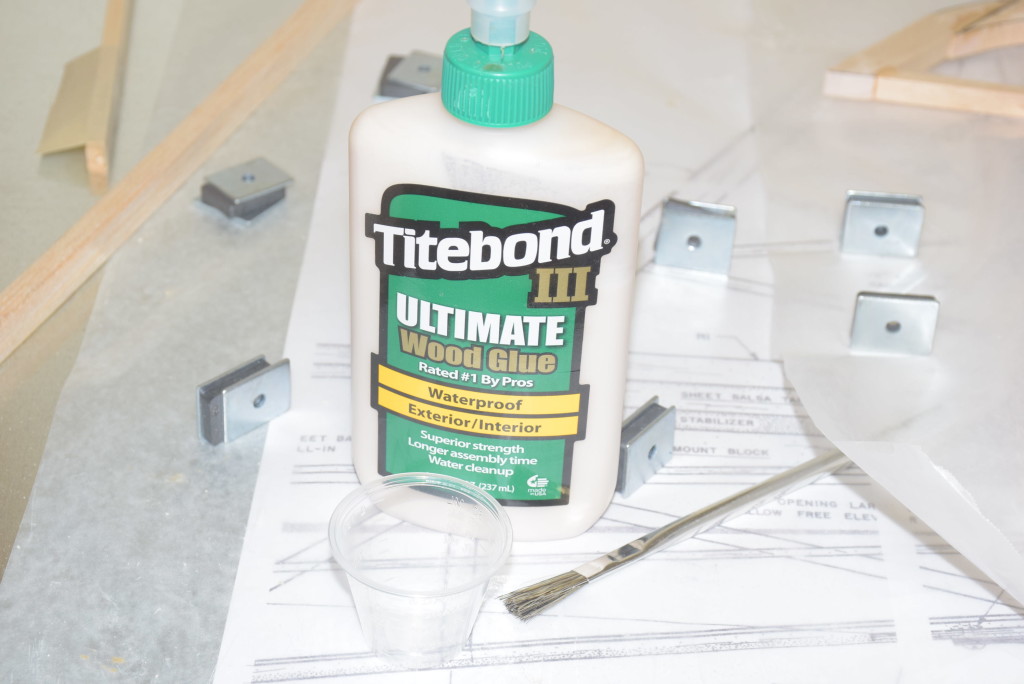

Next, I began to glue up the rest of the printed elevator parts. I took time here to make sure each piece had a very solid and accurate glue joint – no gaps. Use a disc sander to shape the edges of the parts accurately. I glued in the parts one at a time and cleaned up any excess glue that would run out from the joint. I used magnets here to hold the joints in their proper position as the glue set up. This was somewhat of a slow process as I used a wood glue and would let each part setup fully (about 30 mins with the type of glue I was using) before going on to the next. Using wood glue here over CA will make the joint very strong and still allow a little flex. Once all the parts were in place I placed some boards with weights on top of the pieces and allowed it to dry over night.

Elevator Bracing

With the main elevator parts fully dry I was now ready to work on the internal bracing. This was done with 1/4 x 3/8 balsa sticks. Using a tip from airfield models allowed me to get very accurate and precise joints! See the tip here: Cutting accurate truss style balsa joints

Once all the bracing is in place, it best to sand the parts to a uniform thickness. I made a sanding block from a 2×4 about 10-12 inches long. I ran this board through an edge jointer to make the sides and bottom very flat and square to each other. I used 120 grit sand paper to get the material to a uniform thickness and then finished with 320 or greater for a nice smooth surface. When sanding balsa it’s not necessary to apply a lot of pressure, just let the weight of the block and sandpaper do the work for you. Also rotate the piece often so you don’t over-sand one particular. It is also a good idea to sand in alternate directions. All in all I probably removed only about 1/32 of an inch of material!

Horizontal Stabilizer

The horizontal stabilizer was built much the same way as described above. I started with gluing in the main center parts and working from the middle outward. Make sure the hinge line is a straight as possible here too!

The internal bracing was done the same way – using a razor blade to accurately mark the proper angle on the balsa stick and then sanded smooth with a disc sander.

Once all the parts were in place I added some weight on top and let it fully cure before sanding it to a uniform thickness.

Once these parts were all fully dry I set them aside to wait their turn during final assembly!

Stay tuned for part 4!