Sig J-3 1/4 Scale Cub Build Series – Part 8 – Rear Formers

Category : Model Airplane Building , Uncategorized

In part 8 we will take a look at installing the rear formers along with the top stringers.

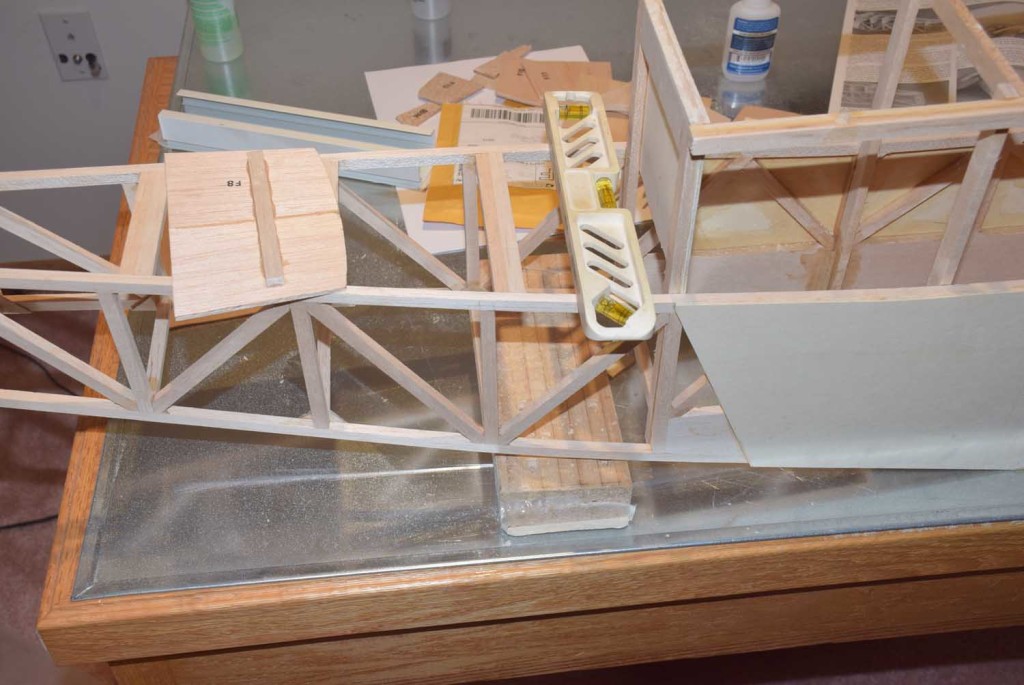

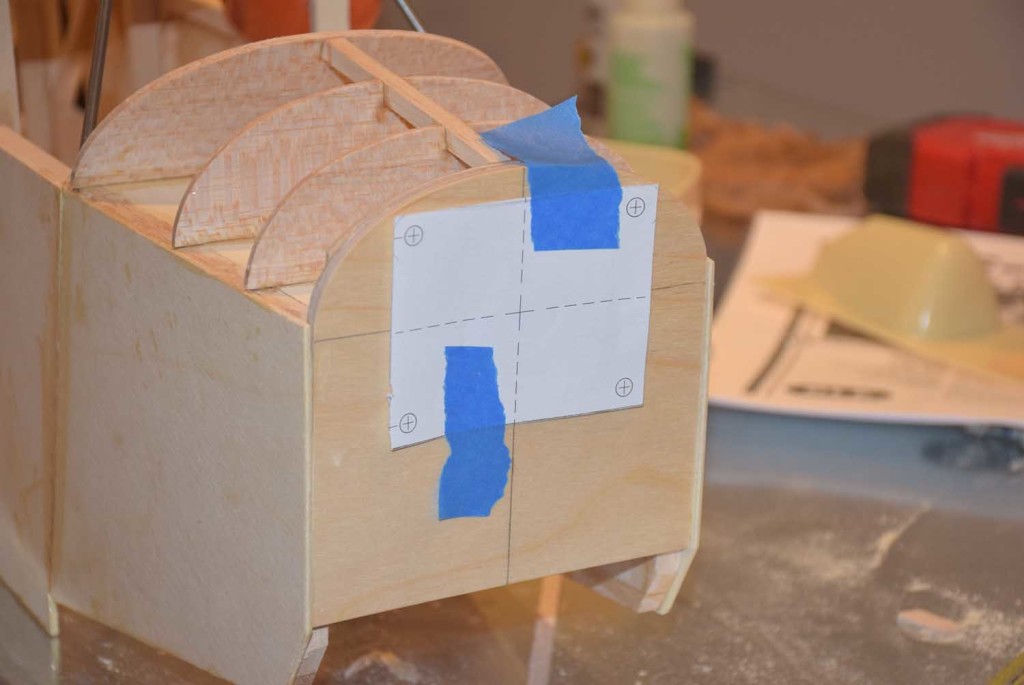

In the photo below you will notice I added some additional cross pieces, this will be used to add in some small reinforcement blocks when gluing the rear formers in place.

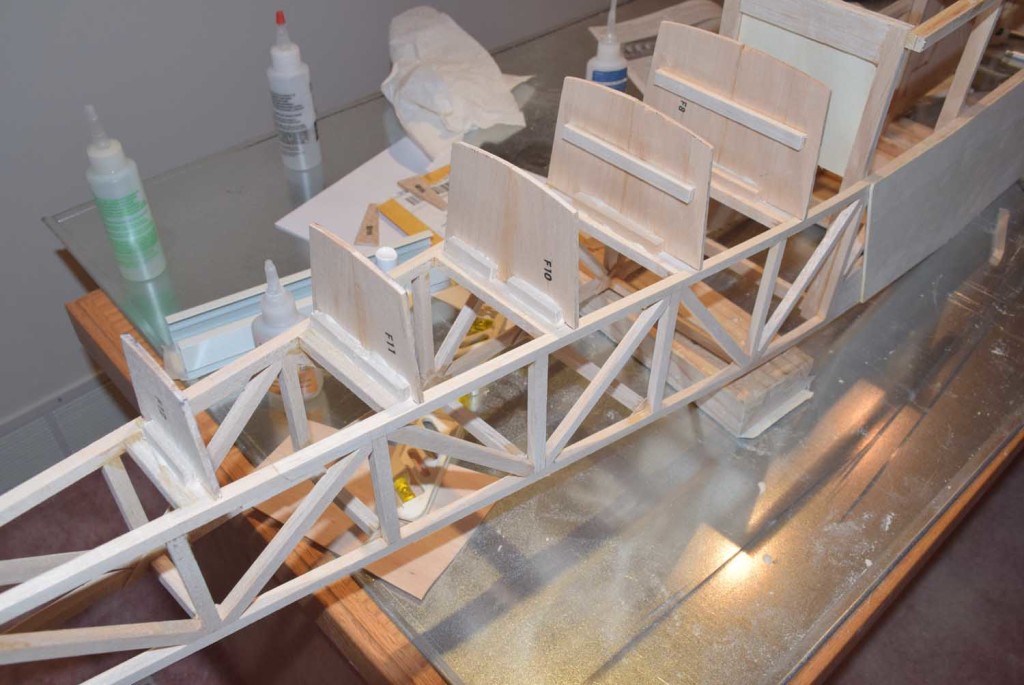

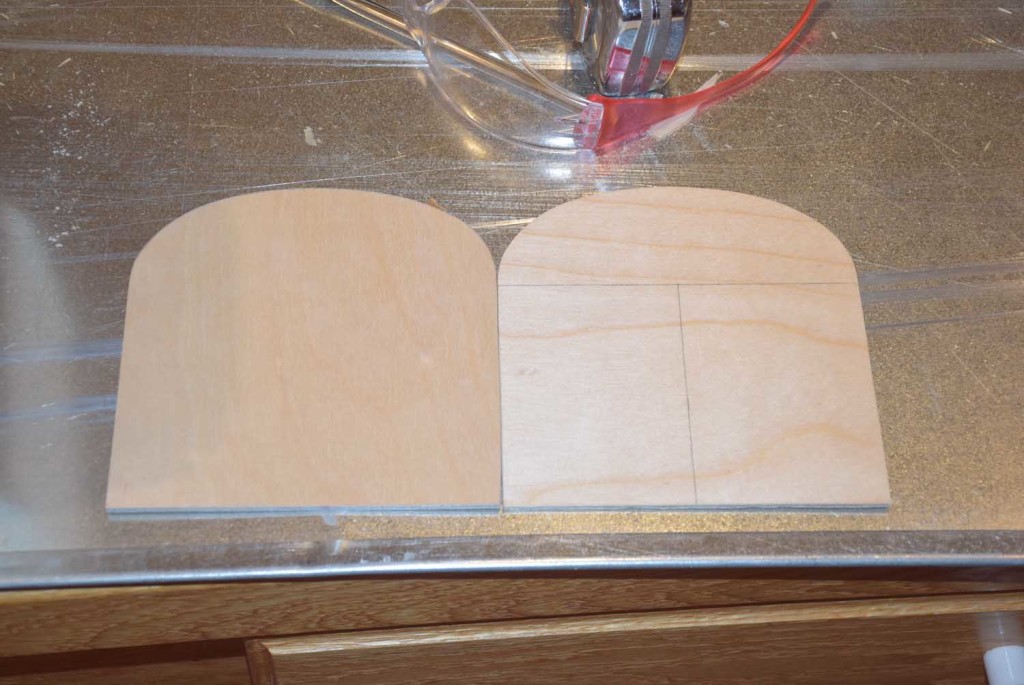

The formers F8-F13 are included with the Sig kit as die-cut balsa. A couple of the larger formers are in two pieces; you will need to glue these together and add a small cross piece for extra strength. (shown in photo above)

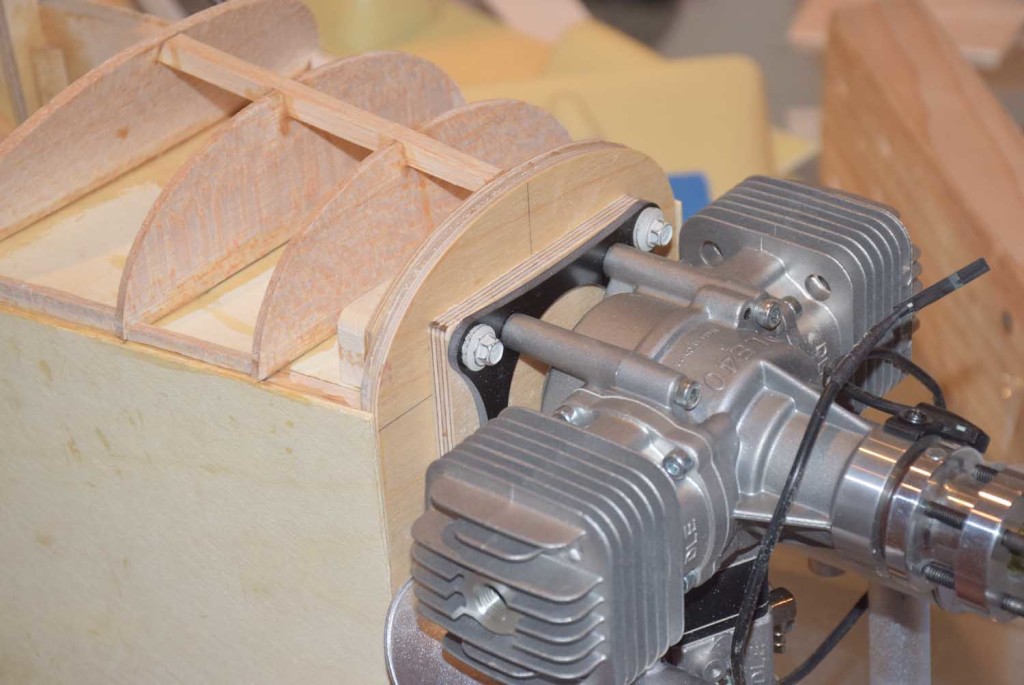

Next, begin by gluing in the largest former and working your way back toward the tail. One thing to note, it is important to line the fuselage up as described in the manual. The formers will be glued in at a small angle relative to the ground. What I did was prop up the fuselage at the required angle with some blocks. Use a small torpedo level to glue the formers in at a 90 degree angle. Using this method will automatically account for the proper angle.

Once all the formers are glued in place, I added some additional blocks behind each former for a some extra support.

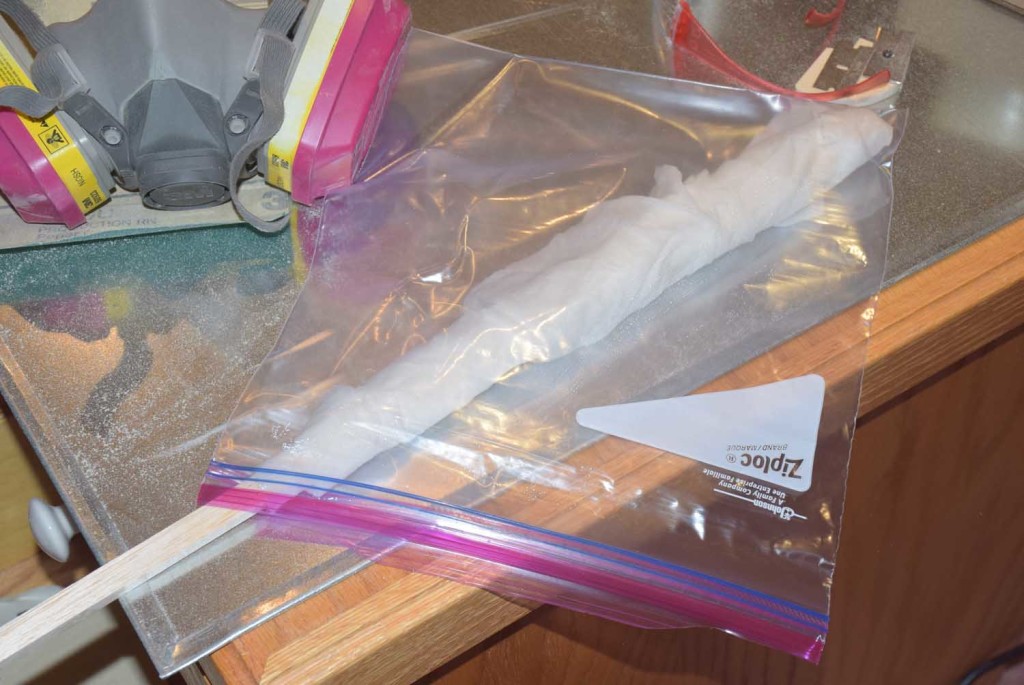

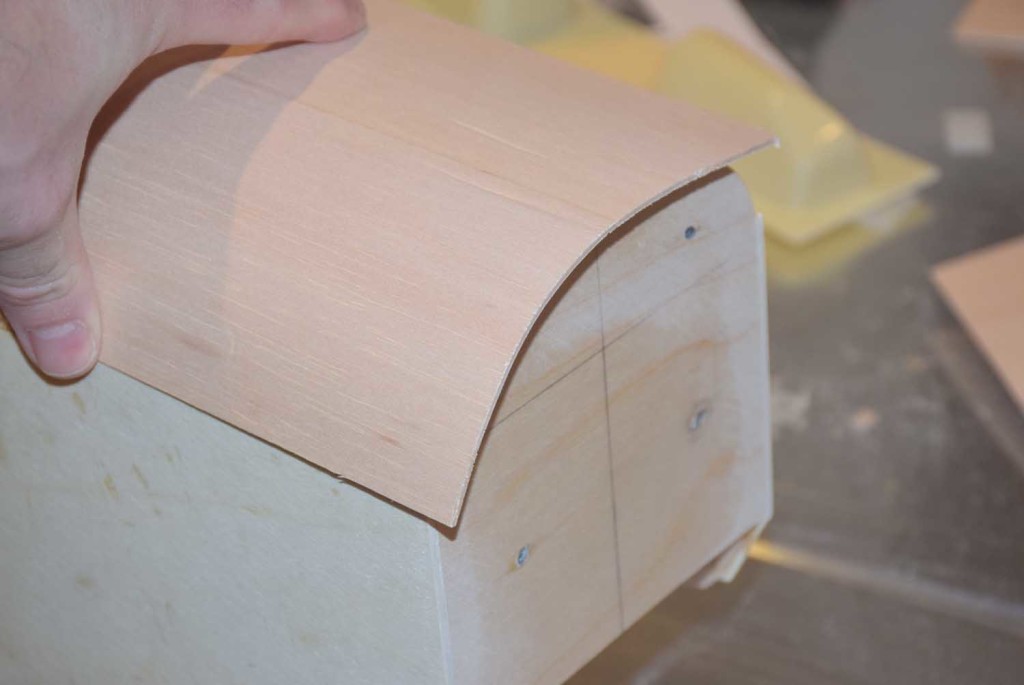

I let these dry overnight before adding the top stringers. The top stringers require you to bend a curve into the 5/16 square stock in order to meet the rear of the cabin. I soaked a paper towel in water and then wrapped the last 12 inches or so of the square stock with the wet towel and placed the ends into a plastic bag. It only required about a 30 minute soak to make them soft enough to work with. I used thick CA here and some kicker so I could quickly get them into position.

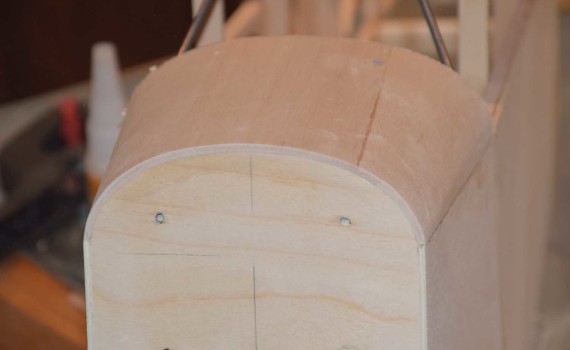

I also added in some additional reinforcement blocks where the stringers meat the rear of the cabin. This will help hold it more secure.

This was a little shorter build article, but once you see the formers in place the fuselage really begins to take shape!

In part 9 we will be taking a look at building a few miscellaneous items: putting in the cabin floor, adding some triangle balsa in the nose, installing the fuselage side stringers and window fill-in posts.